Preparation Method of Benzyl Acetate manufacture

Benzyl Acetate is one of the most produced varieties in synthetic fragrances, and is mainly used in fragrance formulations in the daily chemical industry. Most of the domestic products are exported and mainly consumed in the Asian and European markets. We are going to talk about four preparation methods of benzyl acetate as well as their merits and demerits here.

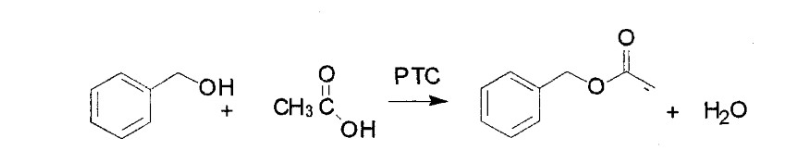

Synthetic Route 1: Benzyl Alcohol Method

Benzyl Alcohol and Acetic Acid interact in the presence of sulfuric acid. After washing off the acid, boric acid is added for vacuum distillation. Benzyl Alcohol was combined with boric acid to form boric acid esters, which was left in the reactor. And Benzyl Alcohol can be recycled by heating boric acid esters with water.

This route is mainly used by some companies in developed countries, such as Friteesche in the United States, DSM in the Netherlands, and H&R in Germany.

The process features simple route, good quality, pure aroma, but high cost of raw materials-the price of the raw material. Benzyl alcohol is almost the same as that of Benzyl Acetate. It is not an ideal method, considering the cost, serious corrosion on equipment, excessive side reactions, complex post-treatment, and large discharge of waste liquid.

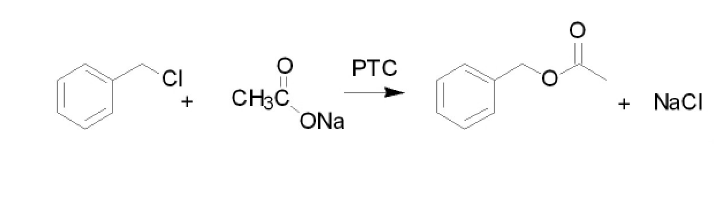

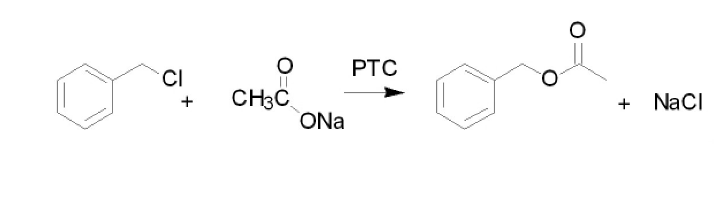

Synthetic Route 2: Benzyl Chloride Method

The reaction of Benzyl Chloride and Sodium Acetate was carried out under the catalysis of phase transfer catalyst. After the reaction, Benzyl Acetate was obtained by distillation. This route is the most economical one, used by most domestic enterprises, such as Tianjin Dacals, Fujian GREEN PINE, etc.

The process is characterized by low cost of raw material and product. However, due to incomplete conversion of Benzyl Chloride, a small amount of it remained, which seriously affected the aroma.

Therefore, the product needs to be refined (hydrolysis, multiple distillation, etc.), resulting in low product yield, generally only about 70%.

Synthetic Route 3: Benzyl Ether Method

After mixing Benzyl Ethe, acetic anhydride and p-methylbenzenesulfonic acid, the reaction lasts 2-6h after heating, and the benzyl acetate crude product was obtained after that. To obtain finished product, it also needs to be filtered, washed, alkaline washed and rectified. Representative companies of this process: AkO and Fritezsche Co., LTD., Wuhan Xuzengboyuan Chemical Co., LTD., Wuhan Organic Industry Co., LTD.

The purity of the product obtained by this method can reach 99.5% or so, and the total yield can reach more than 80%.

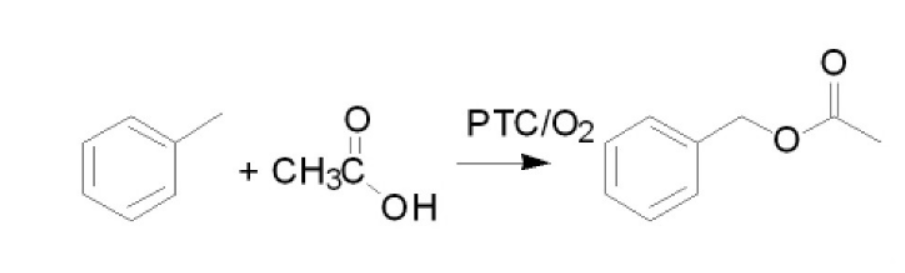

Synthetic Route 4: Toluene Method

Under the action of catalyst, toluene and acetic acid were injected with oxygen to produce Benzyl Acetate in one step. The process is simple and the by-product is water, which is relatively green. But the high pressure required by the reaction, strict requirement for the production equipment, and poor operation security make it not suitable for industrial production.