Advances in the production of butyric acid by biotechnology (I)

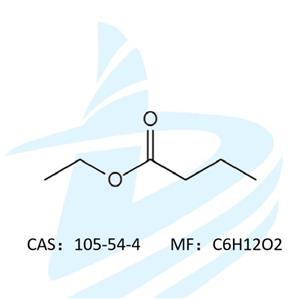

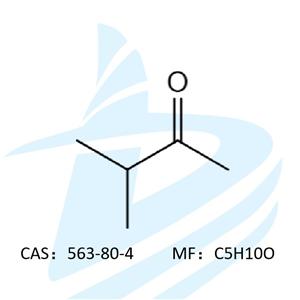

Butyric acid, as an important chemical raw material has been widely used in people's livelihood industries. In the field of food, butyric acid and its derivatives can be directly added to food as food additives to enhance the flavor of food. For example, butyrate can produce an attractive aroma, widely used as a spice in food. sodium butyrate as a new feed additive is gradually replacing traditional antibiotic additives. In the pharmaceutical industry, Butyric acid as a short-chain fatty has a good therapeutic effect on enteritis, and butyric acid can prevent histone from removing ethylene phthalate. So it can prevent the expansion of cancer cells and has an anti-cancer effect. In addition, butyric acid is expected to replace the traditional soil fumigation agent because microorganisms do not resist it. Nowadays, butyric acid is mainly produced from petroleum. Because of the instability and unsustainable supply of crude oil in the world. Butyrate biotechnology fermentation has attracted close attention. The advantages of biological fermentation are as follows: the raw materials used are more extensive, fermentation process belongs to the typical anaerobic process, low energy consumption, low environmental pollution, and sustainable feeding to produce butyrate. Therefore there is increasing emphasis on microbial fermentation to produce butyric acid. The process of cell metabolism of butyric acid production by microbial fermentation is as follows: first,butyric acid-producing bacteria change carbohydrates into pyruvate (PA) by glycolysis, pyruvate, and coenzyme A form acetyl coenzyme A, Then the acetyl-coenzyme is A into butyric coenzyme by saturated fatty acid synthesis pathway A, and some butyric coenzyme is directly converted to butyric acid when butyric acid kinase exists, Some butyryl coenzyme A bind to acetyl coenzyme A transferase to form butyryl coenzyme A: acetyl coenzyme A transferase. This transferase can produce butyrate under certain conditions and acetyl coenzyme A, Some acetyl coenzyme is generally considered to be the main enzyme in butyrate production. The growth conditions of butyric acid-producing strains are basically the same when butyric acid and acetic acid are synthesized, and lactic acid is produced when the growth of such strains is slow ꎬ At the same time, when the amount of fermentation broth pH and undissociated acid changes, butanol and acetone can be produced. Therefore, how to obtain a single butyric acid product is an important direction of genetic transformation.