A Decolorization Method of Benzyl Benzoate Refining

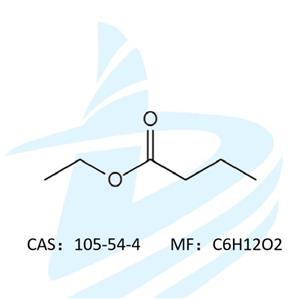

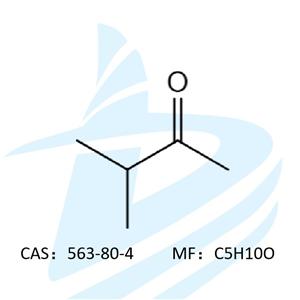

Benzyl benzoate is a colorless, oily liquid with a pleasant aromatic odor and is mainly used as an artificial musk,fragrant and other spices solvent, floral flavor and Yilan flavor blending spices. Clinically used in scabies, also used in body lice, head lice and pubic lice, also used in the preparation of pertussis drugs, asthma drugs and used as insect repellent, acaricide. In industry, benzyl benzoate is manufactured to be widely used as plasticizer and solvent of fiber of acetic acid and nitric acid. At present, benzyl benzoate is mainly manufactured by the following methods: Fractionation of methyl benzoate by transesterification of benzyl alcohol with sodium carbonate as catalyst;Sodium benzyl alcohol and benzaldehyde were heated and refined;The reaction of sodium benzoate with benzyl chloride, the esterification of benzoic acid with benzyl alcohol, and the recovery and refining of by-products in the process of toluene air oxidation. Among the above production methods, benzyl benzoate products or crude products have the problems of dark color and high color number, especially benzyl benzoate recovered by-products during toluene air oxidation. The color number is more than 150 Hazen, which largely limits its scope of application. The patent US6491795 proposed the technology of solvent recrystallization decolorization in the recovery process of benzyl benzoate. The aqueous solution of fatty alcohol containing 1~5 carbon atoms was used as solvent to recrystallize benzyl benzoate fraction at -30~10℃. Benzyl benzoate with 20 Hazen was obtained. The content is more than 99.5 and the yield is higher than 60%. A research provided the technology of redox decolorization and recrystallization decolorization of benzyl benzoate in the study of toluene air oxidation process and comprehensive utilization of by-products, that is, adding hydrogen peroxide and sodium bisulfite to the crude product of benzyl benzoate for redox reaction, removing the main chromogenic impurities, and then recrystallizing the benzyl benzoate with color ≤20 Hazen in isopropanol solution. The yield is about 65% and the purity is higher than 99%. The patent CN107501098A provided the technology of adding active metal and acid solution to the crude product of benzyl benzoate to separate the oil layer and vacuum distillation dehydration to obtain benzyl benzoate ≤60 Hazen. In the process, benzyl benzoate has almost no loss. this method is limited in its application because of the use of metal and acidic solutions. Although the above other methods can obtain benzyl benzoate with low color, but the yield is low, a large amount of wastewater will be produced. In order to solve the defects and shortcomings of the below technology, an research was invented to provides a decolorization method of benzyl benzoate with advanced technology, simple operation and more environmental protection. The benzyl benzoate with higher color number or the mixture mixed with decolorizing solvent was treated with active alumina by decolorizing agent, and the colored impurities in benzyl benzoate were adsorbed on the active alumina. Thus, benzyl benzoate with low color was obtained. The colored impurities (mainly ketones) adsorbed on the active alumina of decolorizing agent were eluted with regenerated solvent, and the regenerated solvent after elution was collected and concentrated and crystallized. Decolorizing agent active alumina can be regenerated and recycled by heating to more than 80℃ to remove solvent. The invention has advanced technology, simple operation and high yield. It is a more environmentally friendly and efficient decolorization method of benzyl benzoate.