Introduction to chemical wastewater treatment technology

化工污水治理技术介绍

Introduction to chemical wastewater treatment technology

01 萃取+MVR+减水剂

Extraction + MVR + Water reducing agent

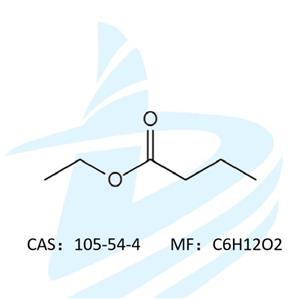

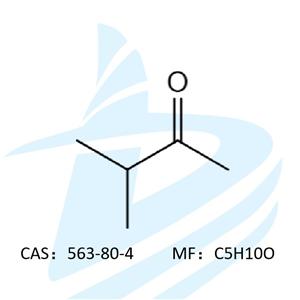

H酸、K酸、吐氏酸等染料及其中间体COD高,盐分高,采用成熟萃取方法,将废水中95%-97%有机物能提取出来,出水无色、无味。我公司通过大量技术改进,国内多个萃取项目萃取技术达到国内领先水平,萃取成本只有国内传统萃取成本40%以下,特别像T酸这种高氨氮、高COD废水优势更加明显。

萃取后无机相通过MVR或三效浓缩提取盐,冷凝液回用。部分有机相我司跟国内实力强的科研机构成功开发出多品种减水剂,变废为宝。

Dyes such as H acid, K acid, and Toxic acid and their intermediates have high COD and high salt content. Using mature extraction methods, 95% -97% of organic matter in wastewater can be extracted. Through a large number of technical improvements, our company has achieved a domestic leading level in the extraction technology for multiple domestic extraction projects. The extraction cost is only less than 40% of the traditional domestic extraction cost. Especially, the advantages of high ammonia nitrogen and high COD wastewater like T acid are more obvious.

After extraction, the inorganic phase is extracted by MVR or three-effect concentration, and the condensate is reused. Part of the organic phase, our company and domestic strong scientific research institutions successfully developed a variety of water reducing agents, turning waste into treasure.

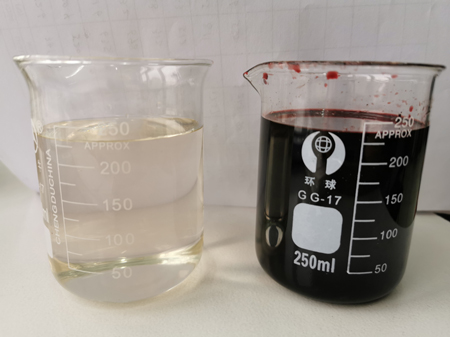

T酸母液处理前后效果图

Effect of T acid mother liquor before and after treatment

本公司萃取技术成功应用于多个项目,下图是本公司一个萃取项目进出水对比图,进水COD65000mg/l,出水COD在1500mg/l,反萃液量很少,出水无色,萃取成本低,技术领先。

The company's extraction technology has been successfully applied to multiple projects. The following figure is a comparison chart of the inlet and outlet water of an extraction project of our company. The inlet water COD is 65000mg / l and the outlet water COD is 1500mg / l. The amount of back-extracted liquid is very small. Low, leading technology.

02 RO+MVR系统RO + MVRO system

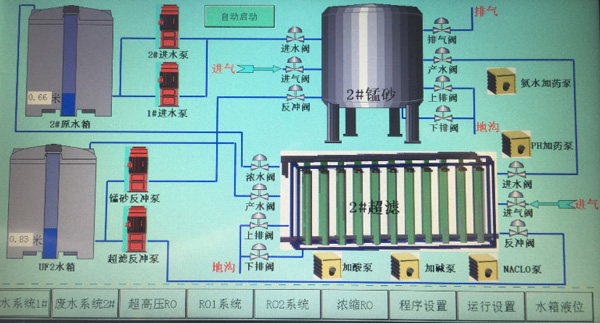

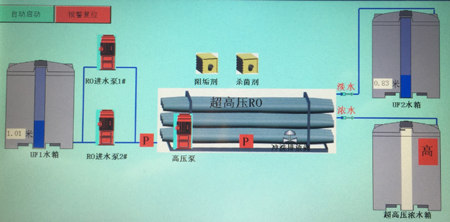

经过处理后废水盐在5%以下,不能直接外排,水量大,直接浓缩成本高,此时可以考虑上RO膜,将废水盐分浓缩到15%左右,再浓缩出盐,这种模式比直接浓缩成本低很多,RO后产水达到中水回用标准。

该系统,我公司具有丰富的工程设计及调试经验,满足客户不同废水定制需求。

After treatment, the salt of the wastewater is below 5%, which cannot be discharged directly. The amount of water is large and the cost of direct concentration is high. At this time, you can consider RO membrane to concentrate the wastewater salt to about 15%, and then concentrate the salt. The cost of concentration is much lower, and the water produced after RO meets the standard for reclaimed water reuse.

This system, our company has a wealth of engineering design and debugging experience to meet customers' different wastewater customization needs.

03 高温催化氧化

采用一定压力及温度对废水进行催化氧化处理,该技术的主要原理是外加的H2O2氧化剂与高效催化剂, 两者在适当的pH下会反应产生氢氧自由基(OH·),通过提高反应温度与高效催化剂结合,氢氧自由基的高氧化能力与废水中的有机物反应,可快速、彻底分解氧化有机物,进而降低废水中生物难分解的COD。

The catalytic oxidation treatment of wastewater is carried out with a certain pressure and temperature. The main principle of this technology is the addition of H2O2 oxidant and high-efficiency catalyst. Both of them will react to generate hydroxyl radicals (OH ·) at appropriate pH. The combination of high-efficiency catalysts, the high oxidizing capacity of hydrogen and oxygen radicals, and the reaction of organic matter in wastewater can quickly and completely decompose oxidized organic matter, thereby reducing the biologically difficult to decompose COD in wastewater

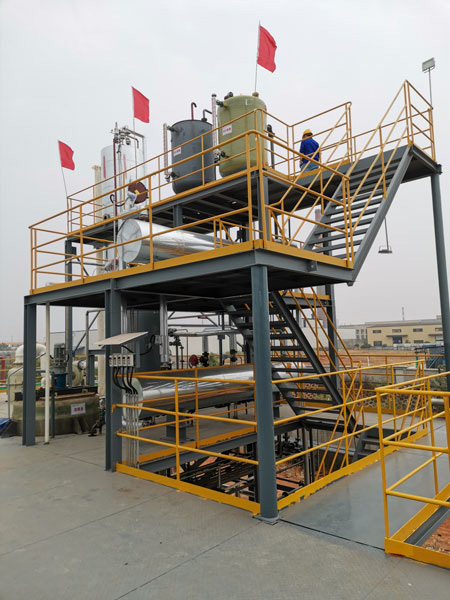

高温催化氧化工程案例

High temperature catalytic oxidation engineering cases