Introduction of ultra-low emission technology for desulfurization, denitration and dust removal

脱硫脱硝除尘超低排放技术介绍

Introduction of ultra-low emission technology for desulfurization, denitration and dust removal

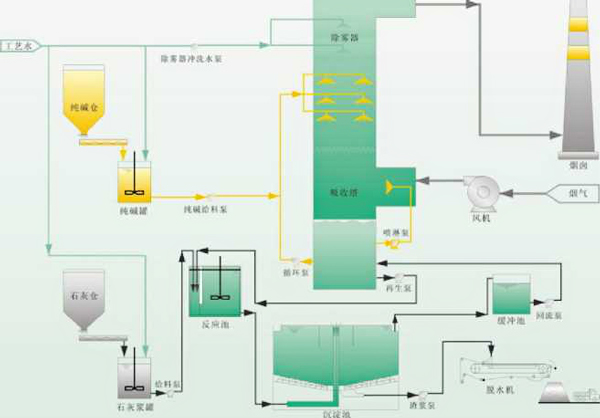

烟气脱硫

Flue gas desulfurization

01脱硫技术 Desulfurization technology

目前脱硫技术较为成熟,通常根据行业及具体工况选择脱硫工艺,在各种技术中,我公司掌握具有优势地位的几种技术如下:

At present, the desulfurization technology is relatively mature, and the desulfurization process is usually selected according to the industry and specific working conditions. Among various technologies, our company has mastered several technologies with a dominant position as follows

1、 碳酸钠脱硫技术

Sodium carbonate desulfurization technology

2、 半干法脱硫技术

Semi-dry desulfurization technology

3、 氧化镁+石灰石脱硫技术

Magnesium oxide + limestone desulfurization technology

4、 改进型双碱法脱硫技术

Improved double-alkali desulfurization technology

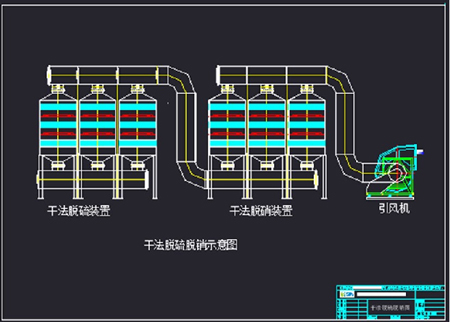

5、 铁锰钙催化吸附干法脱硫技术

Iron-manganese-calcium catalytic adsorption dry desulfurization technology

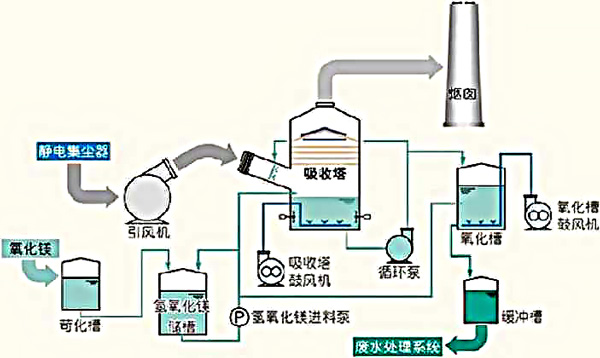

02氧化镁脱硫技术介绍

Introduction of magnesium oxide

desulfurization technology

03双碱法脱硫技术介绍

Introduction of double alkali desulfurization technolgy

04铁锰钙催化吸附干法脱硫剂产品介绍

Product introduction of FeMnMnCa catalytic adsorption dry desulfurizer

BLd-1801型为转化吸收双功能低温脱硫剂,可用于锅炉烟气,天然气等烟气中二氧化硫的脱除。具有脱硫精度高,穿透硫容大,强度好,价格低,流程短费用低等特点。

BLd-1801 is a conversion and absorption dual-function low-temperature desulfurizer, which can be used for the removal of sulfur dioxide in flue gas such as boiler flue gas and natural gas. It has the characteristics of high desulfurization accuracy, large penetration sulfur capacity, good strength, low price, short process and low cost.

烟气脱硝 Flue gas denitrification

目前脱硝技术较为成熟,通常根据行业及具体工况选择脱硝工艺,在各种技术中,我公司掌握具有优势地位的几种技术如下:

At present, denitrification technology is relatively mature. Denitrification process is usually selected according to the industry and specific working conditions. Among various technologies, our company has mastered several technologies with a dominant position as follows:

1、悬浮催化剂SCR脱硝技术

Float catalyst SCR denitration technology

2、低温氧化还原脱硝技术

Low-temperature redox denitration technology

3、 铁锰催化吸附干法脱硝技术

Fe-Mn catalytic adsorption dry denitration technology

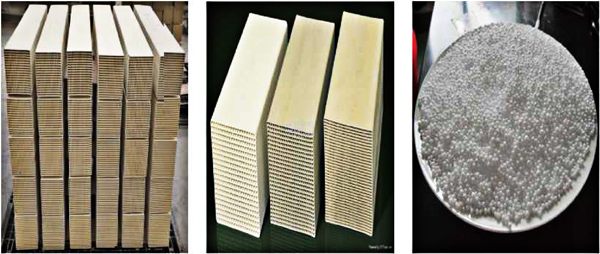

01悬浮球SCR催化剂

Floating ball SCR catalyst

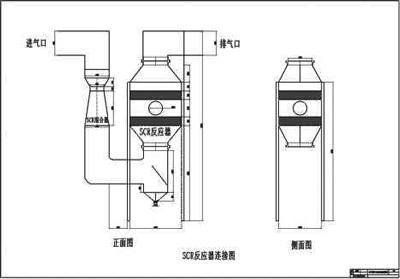

02悬浮球SCR反应器

Floating ball SCR reactor

03铁锰催化吸附干法脱硝技术优势

Advantages of Fe-Mn catalytic adsorption dry denitration technology

-脱除氮氧化物效率可达85%以上.

The efficiency of NOx removal is over 85%.

•系统非常简单,可用率更高,通常可达97% - 99%

The system is very simple, with higher availability, usually up to 97-99%

・投资费用低得多(低50%以上)

Investment costs are much lower (more than 50% lower).

-没有腐蚀,吸收塔及后部设备、烟囱不用防腐。

There is no corrosion, and the absorption tower, rear equipment and chimney do not need to be anticorrosive.

•烟气不需用GGH加热和消白。

GGH heating and whitening are not required for flue gas

-没有废水排放。

No wastewater discharge.

-运行、维护费用低得多(比湿法低30%以上)。

Operating and maintenance costs are much lower (over 30% lower than wet process).

•低水耗。

Low water consumption.

-低功耗(30%以上)

Low power consumption (over 30%).

・占地面积小。 Small floor area

・不需要增加消白系统,大幅减少投资和运行费用。

There is no need to increase the whitening system, greatly reducing the investment and operation costs

04铁锰催化吸附干法脱硝技术介绍

Fe-Mn catalytic adsorption dry denitration technology